Production

If you are looking for safety-critical system solutions, then CUONICS GmbH is the right partner for you. We are a company based in Straubing and we manufacture highly complex safety-critical components and subsystems that meet the highest standards of quality and traceability, ranging from prototypes to pre-series and series production. We are quick and flexible in implementing your requirements.

The manufacturing and assembly of devices, assemblies, and cable harnesses are carried out in accordance with our norm-compliant processes and instructions to ensure product compliance and high quality.

We are also a certified manufacturing company in accordance with LBA Part 21 G.

Expert Information

We are a company specializing in high-mix, low-volume production. With our 1000 square meters of state-of-the-art machinery, we can carry out PCB assembly, inspection, painting, integration/device assembly and end-of-line testing. We employ machines and processes to ensure in-depth quality assurance. Additionally, we support our production with 2.5D solder paste inspection, 3D optical inspection, and X-Ray CT.

We are also capable of handling the cleaning and coating of electronic assemblies and assembling assemblies and cable harnesses. To ensure the quality of our products, we conduct extensive acceptance tests, burn-in tests, and environmental stress tests. Our customers benefit from our comprehensive expertise and commitment to the highest quality standards.

At our production site in Straubing, we produce highly complex safety-critical components and subsystems that meet the highest quality and traceability requirements. Our quality management system is certified in accordance with DIN EN 9100 and Part 21G.

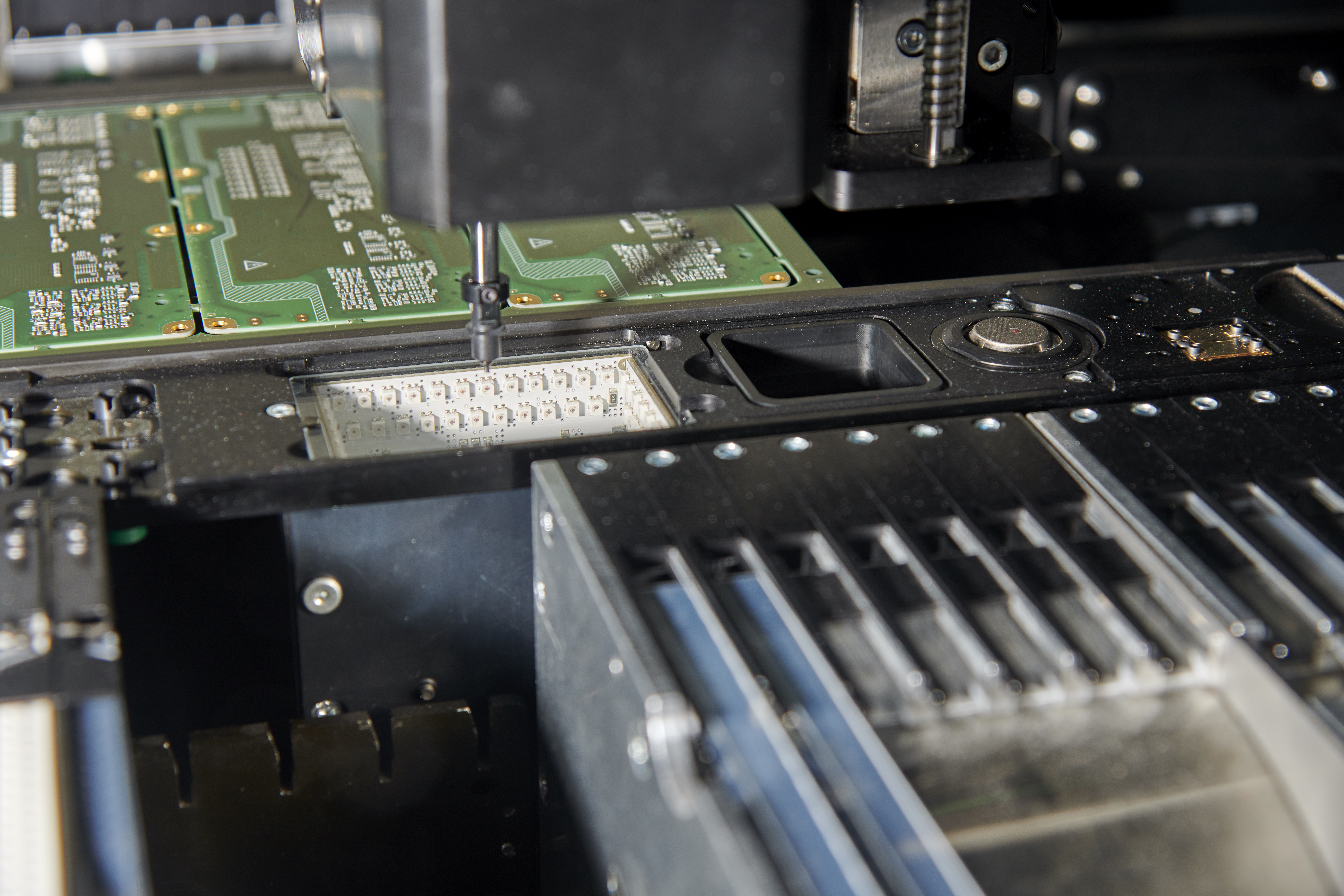

PCB production and assembly process

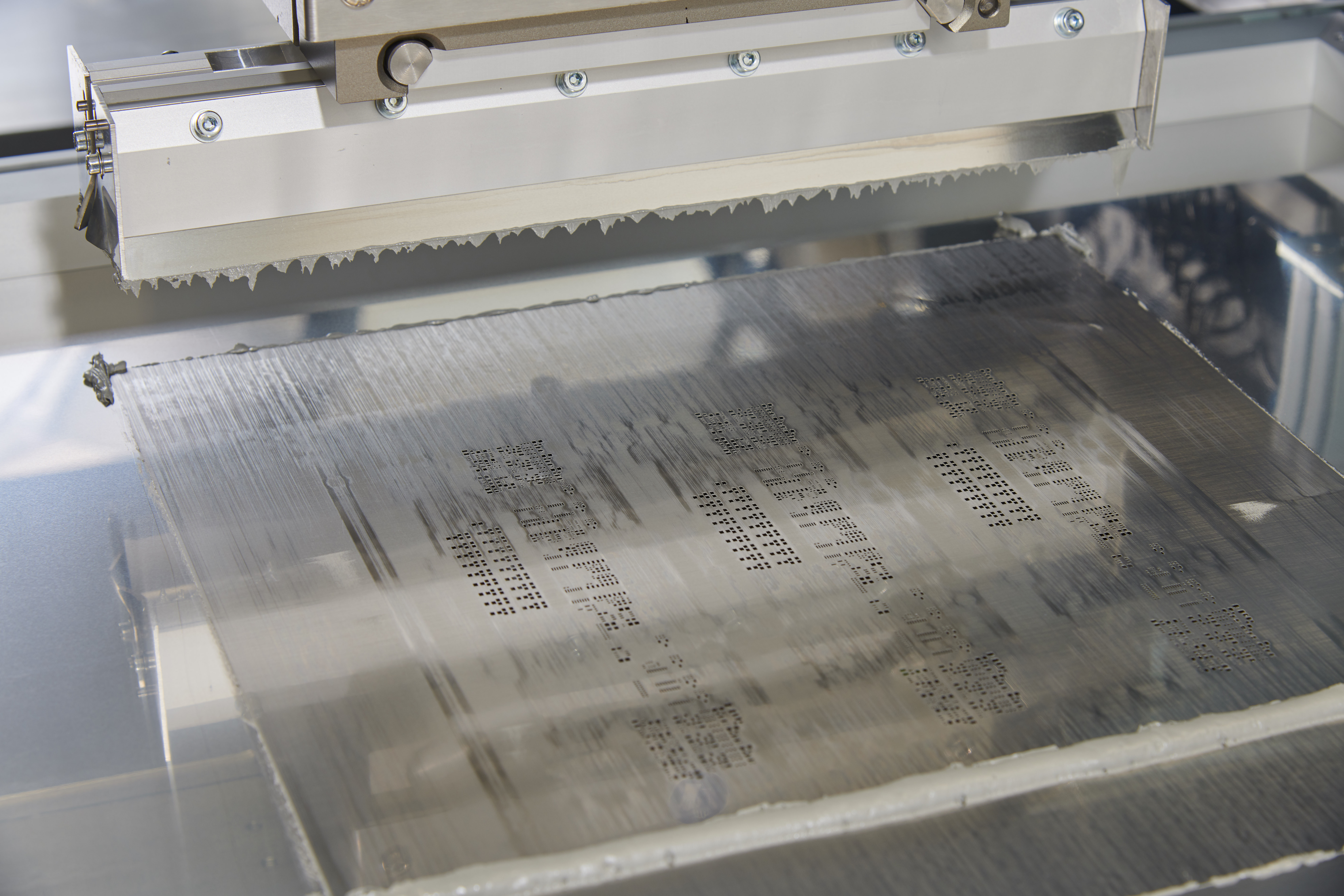

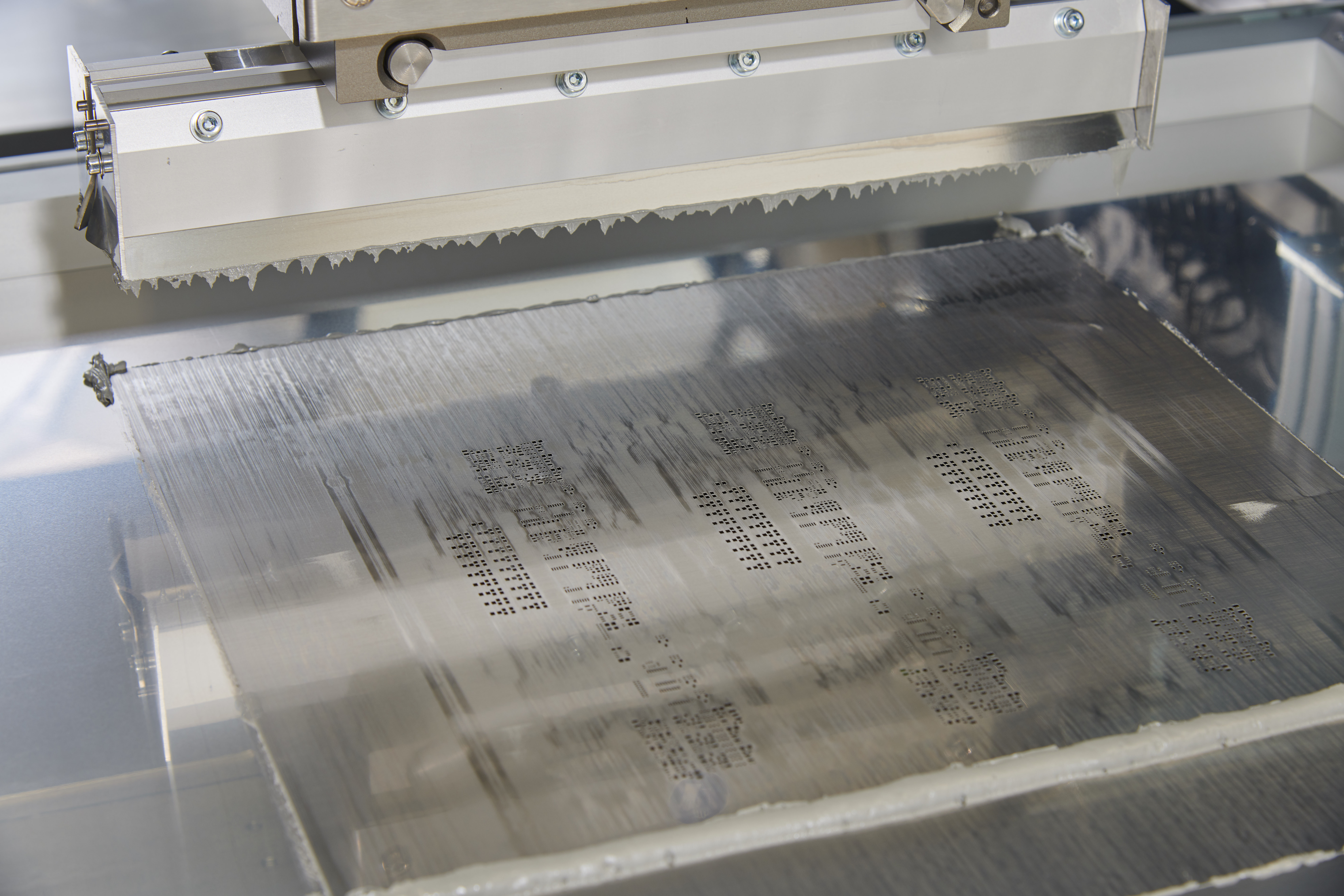

Solder paste application:

The solder paste is applied fully automatically with our ERSA Versaprint2 stencil printer.

An integrated 2.5 D inspection system is used to check the print quality.

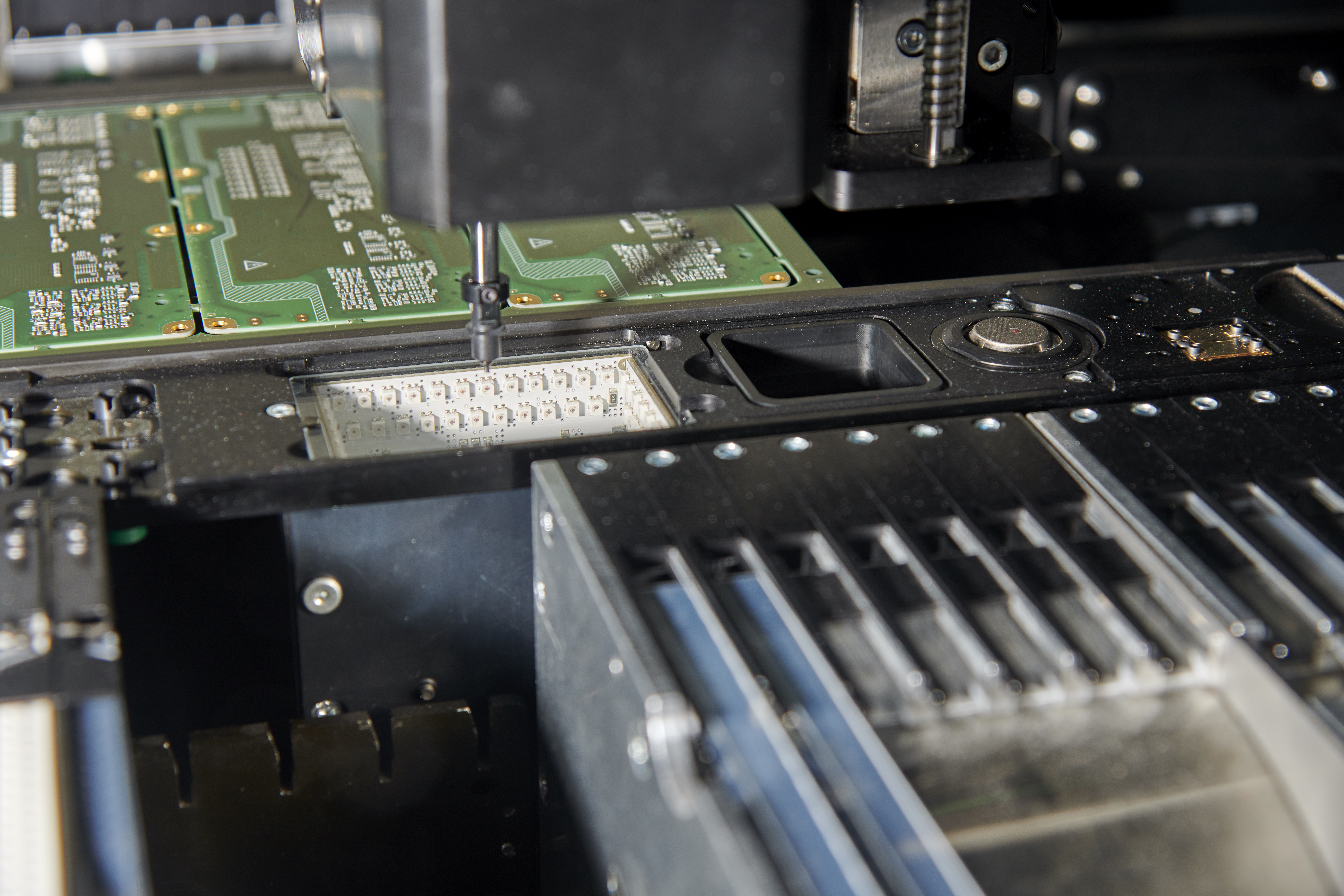

Component assembly:

Electronic components are assembled using the flexible and highly accurate FOX and PUMA pick & place machines from ESSEMTEC.

- FOX: Dosing valve for applying SMT adhesive after the stencil process

- PUMA: 4 pick & place axes for handling larger quantities

Traceability functions:

- Control mechanisms to prevent incorrect machine settings, e.g. incorrectly set up components

- Camera-based checks of the correct enclosure type

- Component Verification Unit (CVU) for measuring passive components such as resistors or capacitors before assembly

- Serial number-based tracking of all assembled components with link to the ESSEMTEC CUBUS storage system

Vapor phase soldering:

The ASSCON VP-800 vapor phase soldering system achieves more effective energy transfer compared to convection systems. This means that even bulky assemblies can be processed without any problems.

An additional vacuum module guarantees a significant reduction in the formation of voids in the solder joints. Among other things, this reduces the risk of thermal overloading of components with a high power loss due to poorly soldered thermal surfaces.

In addition, all process parameters are archived.

Assembly inspection:

Electrical and optical test procedures, checked by trained personnel – on this basis, we check whether an assembly meets the requirements.

Maximum product safety and conformity through:

- Ongoing quality assurance measures for assembly production in accordance with IPC-A-610 and in-house specifications

- Checking the solder paste print for short circuits, missing solder paste and other faults

- Inspection of PCB assembly by an experienced quality assurance team, supported by an automatic optical inspection system (AOI) and an X-ray CT system (AXI) with a resolution of up to 10 μm

- 3D AOI OMRON, 360° side cameras, OCR character recognition, connection to traceability

- 3D X-ray CT OMRON, fully automated analysis of BGA, QFN, THT, Pressfit etc.

- Long-term tests to detect early failures (burn-in, run-in)

- Temperature tests, thermal stress simulation of assemblies

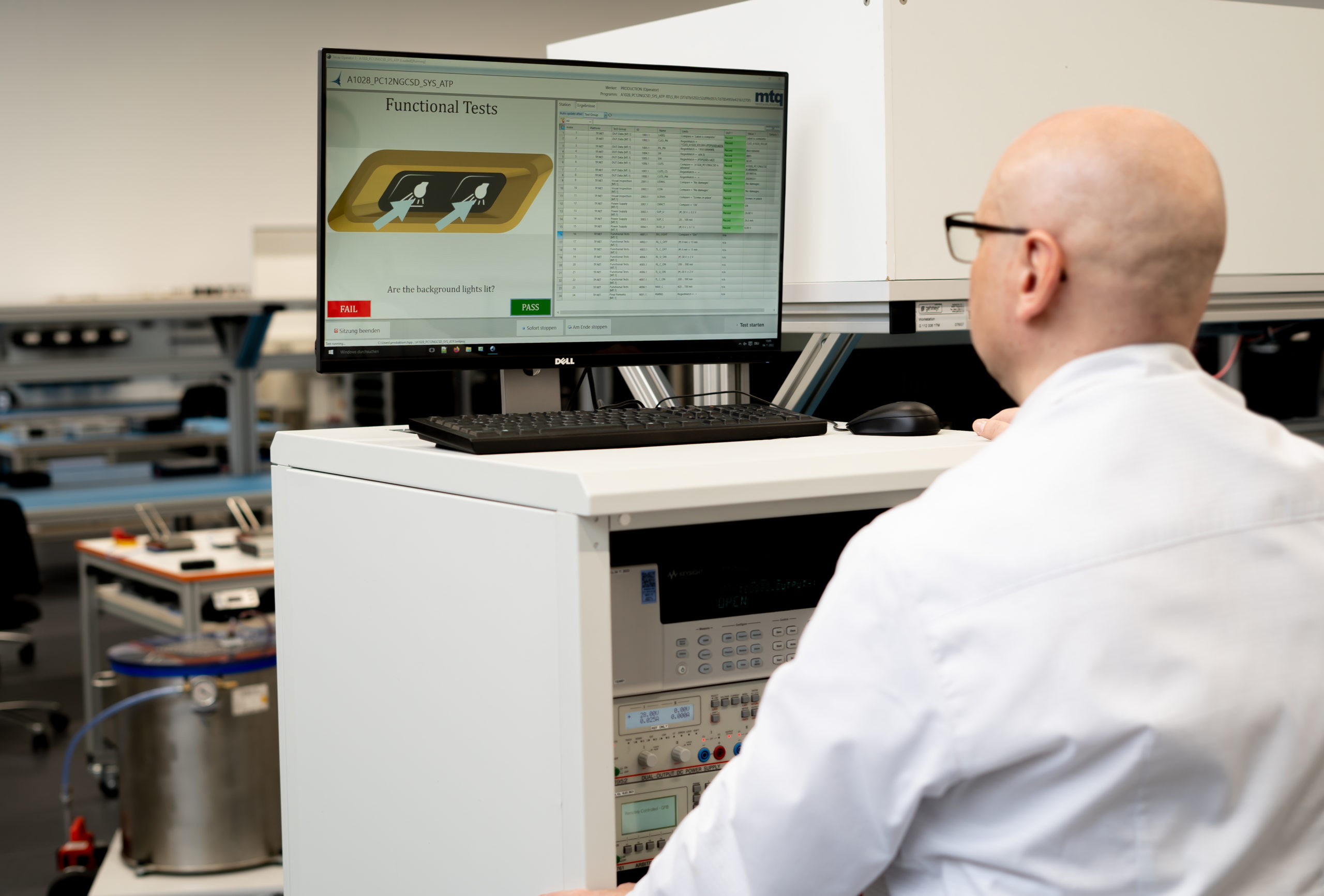

- Functional tests of the assemblies/devices

Assembly cleaning:

In order to achieve a permanently reliable and conformal coating, all impurities from production, such as resin residues, activators, impurities from material handling, etc., must be removed.

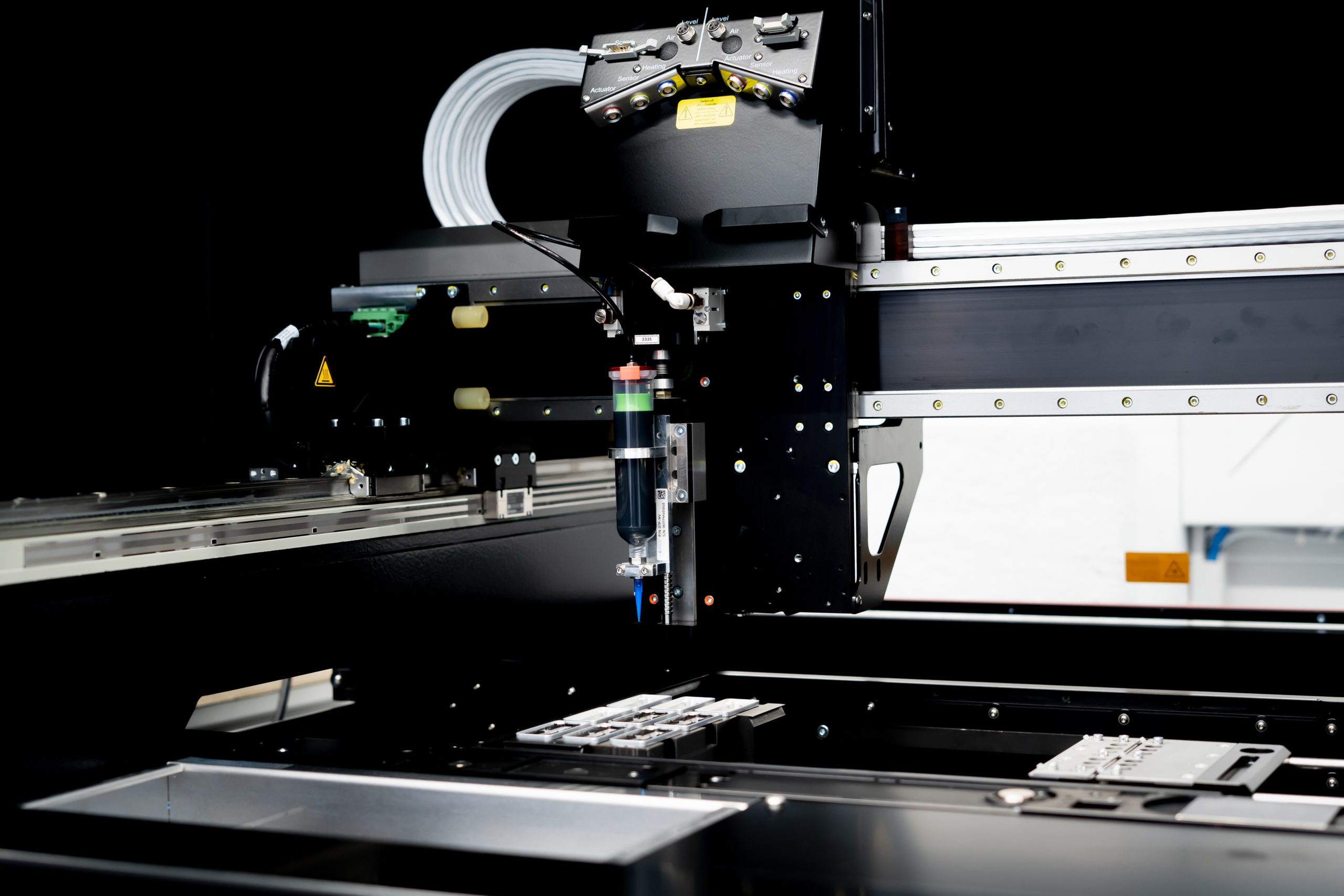

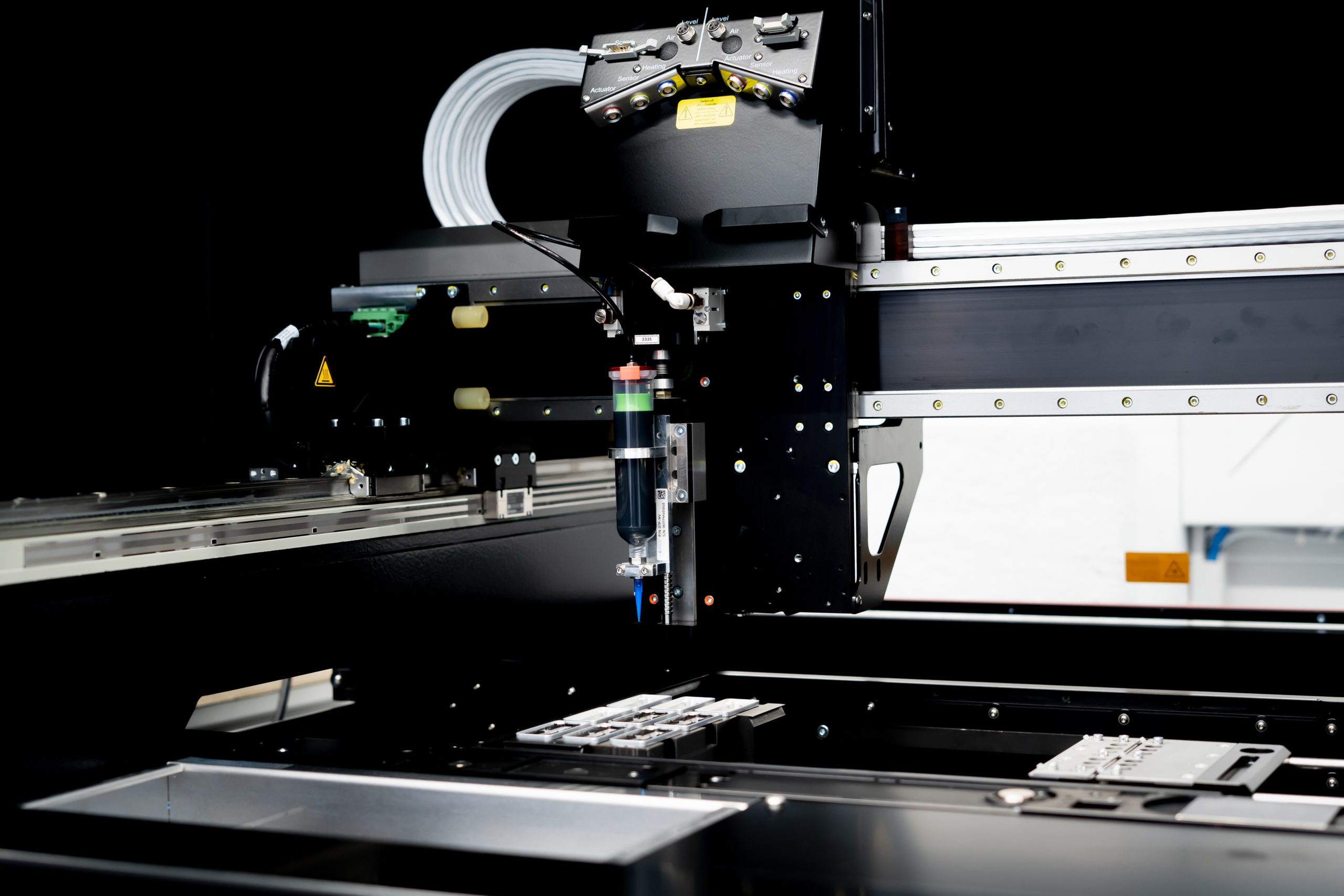

Special processes:

The flexible ESSEMTEC SPIDER dosing system enables a wide range of special processes to be carried out.

Solder paste

AIM REL-22 RoHS

AIM REL-61 RoHS

AIM SAC-305 RoHS

AIM M8 Leaded

SMT-Adhesive

Loctite 3609

Underfill

Loctite UF-1173

Dam & Fill

Peters SL1307-HT

Peters SL1307-T

3D-Application

DOWSIL 732

Component-Coating:

The assemblies are coated using the REHM Protecto XC coating system, which enables us to carry out a reliable conformal coating process that provides the electronic assemblies with lasting protection against environmental influences. The coating medium is heated to 35°C to ensure a stable viscosity during the coating process.

In addition, the inspection belt with integrated UV light enables direct process control after the coating application.

All PCBs are cured with temperature-controlled ovens, Binder FED-400.

Overview of our production machines:

| Manufacturer | Machine type | Process |

|---|---|---|

| ERSA | Versaprint2PRO² | Solder paste application & solder paste inspection (SPI) |

| ESSEMTEC | FOX | Pick & place, dosing of SMT adhesive |

| ESSEMTEC | PUMA | Pick & Place, 4 axes |

| ESSEMTEC | SPIDER | Application of various adhesives (SMT adhesive, underfill, silicone), solder paste, dam & fill, 3D application, etc. |

| ESSEMTEC | CUBUS-L | Automatic storage of components, capacity up to 3,000 component rolls |

| OMRON | VT-S730 | 3D AOI system |

| OMRON | VT-X700-E | 3D AXI system for inspecting components soldered on the underside |

| PBT WORKS | SuperSwashIII | Cleaning printed circuit boards and stencils |

| Rehm Thermal Systems | Protecto XC | Coating of electronic assemblies |

| ASSCON | VP-800 | Vapor phase with vacuum module |

General production possibilities:

- Manual soldering of SMT and THT components according to J-STD-001

- Degilding process for removing the gold plating, e.g. connector pins

- Reworking of electronic assemblies in accordance with IPC-7711/21. All PCBs are dried before reworking to minimize the stress on moisture-sensitive components

- Customized wire harness production

- Maintenance work on existing assemblies to maintain or increase availability

Procurement and storage

We offer you a wide range of logistics options, including the procurement of necessary components, testing of materials based on relevant data and storage in special storage systems. Our automated CUBUS warehouse system supports us in the complete traceability of all warehouse movements. MSL components can be reliably sealed against the ingress of moisture in moisture barrier bags, together with an indicator and silica bag.

Quality Assurance

We consider quality assurance from both a process and product perspective. Continuous monitoring of the implemented processes and the resulting work outcomes ensures consistent, process- and norm-compliant actions, as well as early error detection in all areas of the company, thus ensuring the achievement of our high-quality standards.

To ensure our high product-related quality standards, quality assurance is intensively integrated into projects as part of our quality management. This integration begins in the project planning phase through the integral processes of RTCA DO-254 or RTCA DO-178C. Quality assurance is also actively involved in verification by participating in acceptance tests, functional tests and reviews. Furthermore, regular internal audits are conducted in all areas.